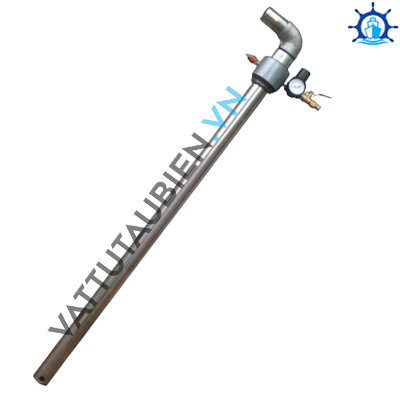

Pneumatic Scaling Hammer

A pneumatic scaling hammer is a powerful tool used for surface preparation, particularly in removing rust, scale, paint, and other coatings from metal surfaces.

It operates using compressed air, which drives a set of chisels or hammers to rapidly strike the surface, effectively breaking up and dislodging the unwanted material.

This tool is essential in various industries, including shipbuilding, construction, and metalworking, where maintaining clean and smooth surfaces is crucial for further processing or painting.

Operating Principle :

-

Compressed Air Supply: The hammer is connected to a source of compressed air, typically via a hose.

-

Air Flow Regulation: The throttle valve controls the amount of air entering the hammer.

-

Piston Movement: Compressed air drives the piston back and forth within the body of the hammer.

-

Impact Action: The piston's movement is transferred to the chisels or hammers, causing them to strike the surface repeatedly.

-

Material Removal: The rapid impact action breaks up rust, scale, paint, or other coatings, which are then removed from the surface.

Applications :

-

Shipbuilding and Maintenance: Removing rust and marine growth from hulls.

-

Construction: Cleaning steel beams and girders.

-

Metalworking: Preparing metal surfaces for welding or painting.

-

Automotive Industry: Removing paint and rust from vehicle frames and parts.

Advantages :

-

Efficiency: Rapid removal of coatings and contaminants.

-

Durability: Designed to withstand harsh working conditions.

-

Versatility: Interchangeable heads allow for use on various materials and surfaces.

Safety Tips :

-

Personal Protective Equipment (PPE): Wear safety goggles, ear protection, and gloves.

-

Proper Maintenance: Regularly check and maintain the tool to ensure optimal performance and safety.

-

Secure Work Area: Ensure the workpiece is securely fixed to prevent movement during operation.

A pneumatic scaling hammer is an invaluable tool for efficiently preparing metal surfaces by removing unwanted coatings and contaminants. Its power, versatility, and durability make it a staple in industries where surface cleanliness is paramount. By following proper usage and safety guidelines, operators can achieve optimal results while maintaining a safe working environment.